Fully automatic sampling system for liquid storage tanks at any height

- BRT

- China

- Please contact the staff

- Please contact the staff

The first domestically developed fully automatic sampling system for liquid storage tanks at any height

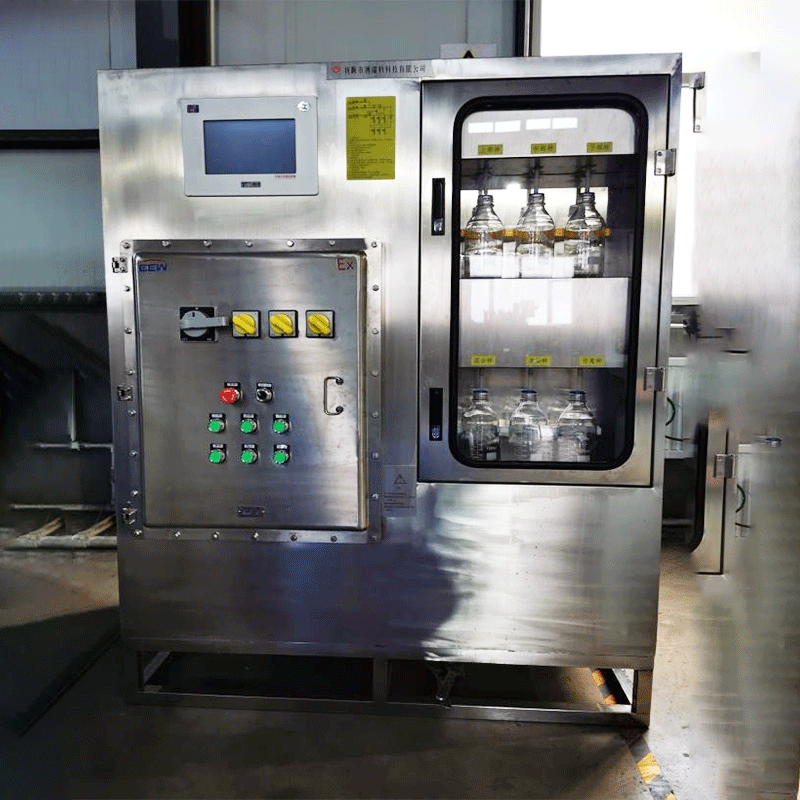

Fully automatic sampling system

Fully automatic sampling system for liquid storage tanks

After years of technological upgrades and reserves, our company has successfully designed and produced the first 《fully automatic sampling system for liquid storage tanks at any height》in China. This sampling system enables a single set of equipment to complete all the sampling functions required for 13 types of tank sampling in GB/T4756-2015 《Manual Sampling Method for Petroleum Liquids》, including upper, middle, lower, combined, bottom, and full layer sampling, which is the first in China.

This sampling system currently holds 12 patents (3 invention patents pending certification; 9 utility model patents). Some of the issued patent certificates are as follows:

一、Technical parameters of fully automatic sampling system at any height below the tank

| working voltage | 380V |

| working power | 2.5KW |

| Ambient Temperature | -40℃~+60℃ |

| Sampling height range | (150-30000)mm |

| Sampling position error | <2% |

| Sampling volume error | <5% |

| Working pressure | 80Kpa~110Kpa |

| Explosion proof type | Ex db[ib Gb] ⅡB T4 |

二、Advantages of fully automatic sampling system at any height below the tank

◆ Can achieve sampling at any height: PLC controls servo motors to achieve positioning sampling at any height

◆ Accurate sampling point position: PLC control, accurate position accuracy

◆ Sampling points are visually visible: real-time display of sampling point location and process

◆ Remote control, fully automatic sampling: fully automatic/manual switchable data traceability

◆ Multifunctional: In addition to completing the 90% sampling function specified in GB/T 4756 standard, it can also adapt to Monitoring liquid level and density during operation

◆ Full system explosion-proof: Non electric mechanical design inside the tank, safe and reliable; Explosion proof design configuration for the entire system outside the tank

◆ Parameters can be set: flow rate, sampling amount, cycle time, and density can all be adjusted

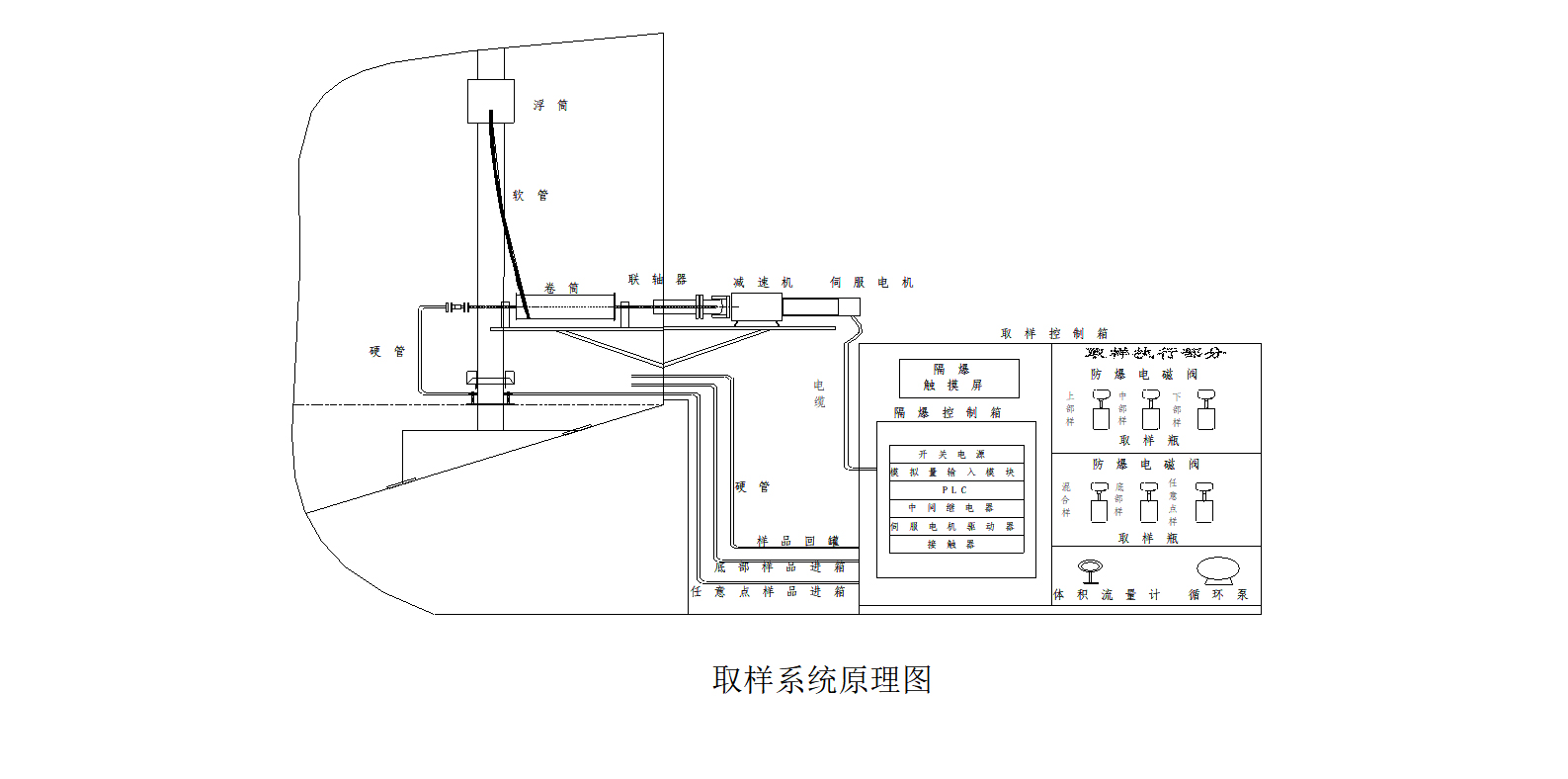

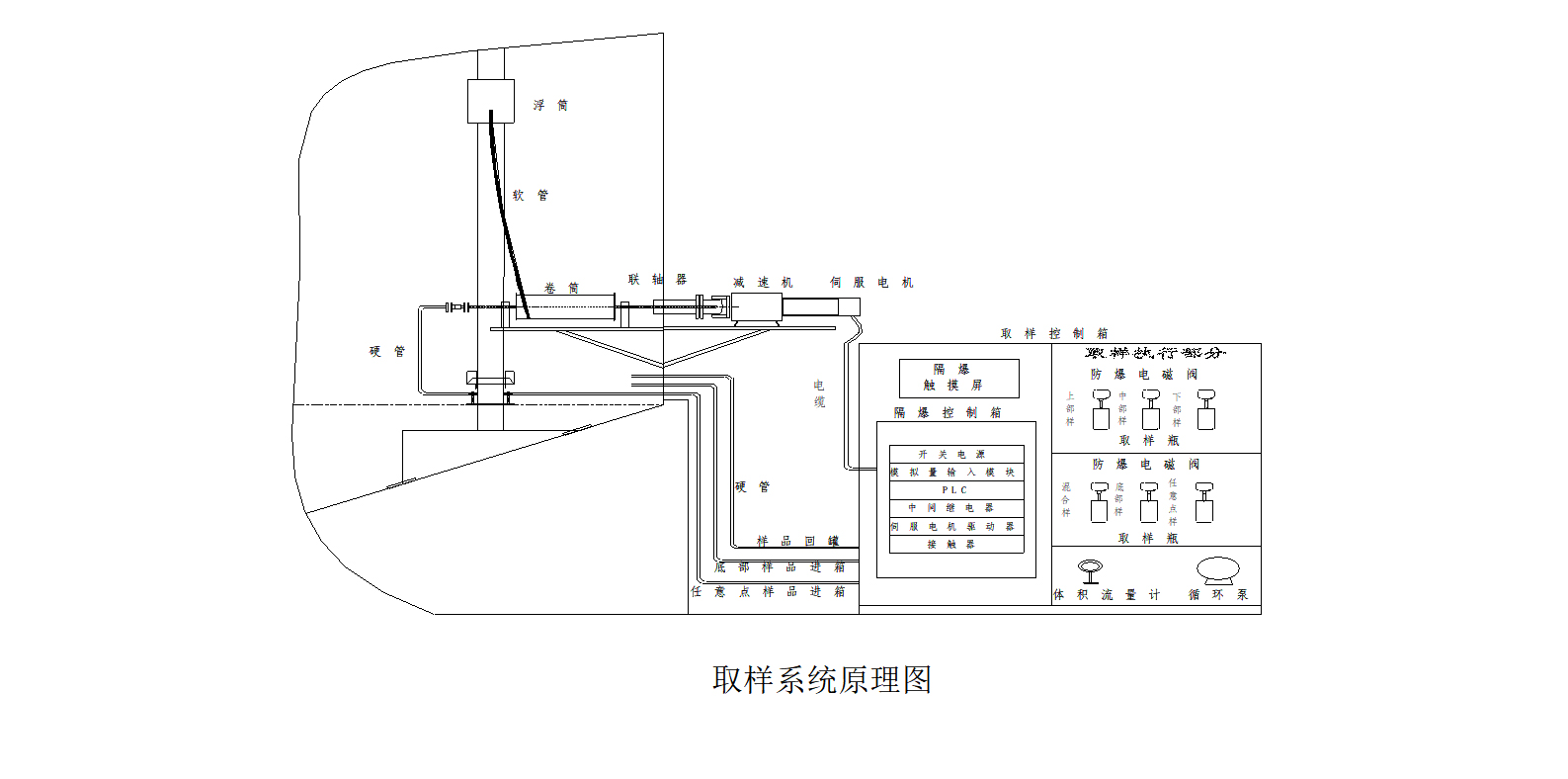

三、Working principle of fully automatic sampling system at any height below the tank

The servo motor outside the tank transmits power through a coupling to achieve linkage with non electric machinery inside the tank. The sampling tubes are arranged in an orderly manner on the drum, and the inlet position of the sampling tubes is controlled through a human-computer interaction system. Sampling can be achieved by inputting the sampling height. The servo motor is connected to the PLC, which can achieve precise positioning of position height with a positioning error of less than 2%.

Input the sampling amount, PLC controls the flow meter, can control the sampling accuracy, and the sampling amount error is less than 5%.

It can be connected to the on-site storage tank level gauge signal, and the interface automatically displays the liquid level height inside the tank. Sampling height, cycle time, sampling volume or quality can be set according to requirements. Sampling can be conducted at any height of the sampling location.

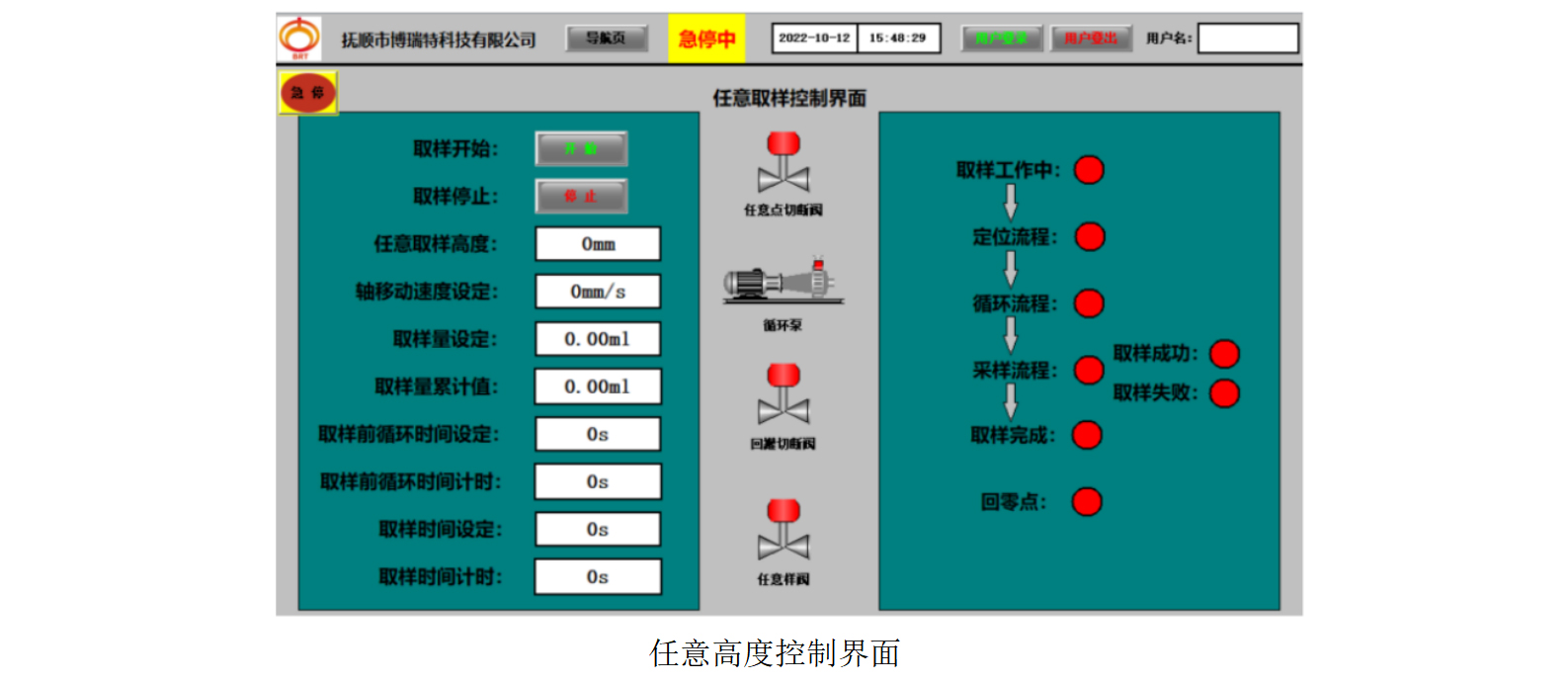

四、Upper computer operating system

The navigation page is clear and concise, and can be used for sampling at any height, mixed sampling, sampling from various parts, and sampling from all parts according to needs. Select the button according to the sampling requirements to automatically complete the corresponding sampling process.

◆ For sampling at any height, click to enter the sampling system dialog box, enter the sampling height, sampling amount, pre sampling cycle time, and sampling time, click the "Start" button, and the indicator lights of each operation process will light up according to the actual working status to observe the progress of the work in real time. After sampling is completed, the internal height positioning system will automatically return to the zero position, and the successful sampling display light will light up.

◆ If you need to stop the sampling work midway, you can press the "emergency stop" button to stop the sampling work at this time.

◆Go to the upper, middle, lower, bottom, and mixed sampling interfaces respectively, and click the "Start" button to complete the sampling.

◆Sampling parameters can be automatically recorded once input, and can also be changed according to requirements each time;

◆ Set the fully automatic sampling function on the fully automatic sampling operation interface. After entering the full sampling interface, set the sampling parameters and click the open button to obtain the upper sample, middle sample, lower sample, mixed sample (mixed at three points), and bottom sample with one click.

五、Installation of sampling system

The installation of the sampling system includes four parts: device entry, mechanical and electrical installation, and overall linkage debugging.

Installation conditions:

① Sampling control box requires installation site hardening and leveling

② On site laying (pre embedded or pipe laying)

a) 380V cable;

b) Tank liquid level signal line;

c) Servo motor power cable;

d) Servo motor signal feedback cable.

③ The target storage tank that requires the installation of a sampling system should be a newly built tank (without oil input) or an old tank that meets the hot work conditions after cleaning

④ Sampling box entry requires lifting operation; The installation of the positioning mechanism requires opening holes and welding on the tank wall, and requires entry into confined spaces for operations, temporary electrical work, and hot work. Before starting work, corresponding work permits must be obtained

⑤ Installation steps

a) All devices and components are in place, and all random accessories and materials are checked for completeness upon unpacking

b) Open a hole on the tank wall on one side of the manual sampling tube

c) Welding coupling paired flange

d) Welding the drum bracket inside the tank

e) Welding the gearbox bracket outside the tank

⑥ Connection between storage tank and sampling box process pipeline

⑦ Electrical control part debugging

六、User Experience

① The second generation product, the 《roller type liquid storage tank bottom sampling device》, was officially launched for use at Zhangjiakou Airport in July 2021 and has been operating normally ever since.

② In September 2023, four sets of BQGS-II type 《fully automatic sampling system for liquid storage tanks at any height》, the third-generation product, will be landed in the tank area of the Capital New Airport and China Aviation Oil Research and Development Center.